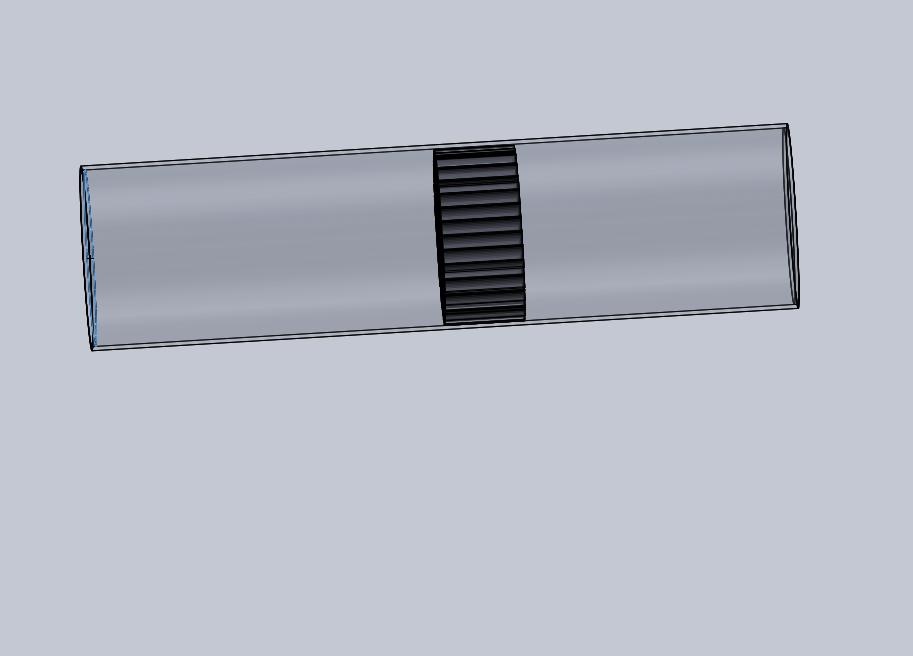

when examining a tube axial fan model, surface goal ofvelocity pressure at outlet in the direction of flow was very highat outlet ,this may be refers to high swirl produced from the fanblades that makes air come and go across this surface ....I 'm notsure .A straightener was modeled to simulate real life to make itstop this swirl and flow through this part was simulated and it'spressure drop was found.it will be assembled inline with the fan .

what is the best way to cancel the drop of the straightener ?

1-to add an inline fan at outlet boundary condition? if so how canI insert Goals at outlet

2- to initially put static pressure below atmospheric pressure atoutlet boundary condition to cancel the pressure drop it a fanelement need to be put inline withSolidworksFlow Simulation

what is the best way to cancel the drop of the straightener ?

1-to add an inline fan at outlet boundary condition? if so how canI insert Goals at outlet

2- to initially put static pressure below atmospheric pressure atoutlet boundary condition to cancel the pressure drop it a fanelement need to be put inline withSolidworksFlow Simulation